| Home page About us Products Contact us Site map E-mail |

|

|

| You are here >> Home page >> Products >> Diamond scribing wheel,diamond glass cutting wheel |

| Diamond scribing wheel,Diamond glass cutting wheel |

| We produce diamond scribing wheel,diamond glass cutting wheel,LED cutting wheel,wheel holder,multi head glass cutting machine, PCD scribing wheels are widely used to cut glass such as LCD panels and substrates, touch screen, auto glass, optical glass, medical glass etc, we have products range of high penetration diamond scribing wheel,medium penetration diamond scribing wheel,PCD scribing wheel,carbide scribing wheel,hybrid diamond scribing wheel,diamond glass cutter,wheel holder,diamond axle,carbide axle,single head glass cutting machine,multi head glass cutting machine,glass engraver,glass grinding wheel,glass twist drill. |

|

Diamond scribing wheel/Glass cutting wheel |

|

|

|

|

|

|

|

|

|

|

|

|

High penetration diamond scribing wheel /LED glass cutting wheel (PCD wheel with cutting teeth )

Features and advantages of high penetration diamond scribing wheels: |

Medium penetration diamond scribing wheel (micro teeth PCD wheel)

|

Diamond scribing wheel (Non teeth LED screen cutting wheel), |

Hybrid PCD scribing wheel (black&white high precision diamond glass/LED cutting wheel) Features and advantages of hybrid PCD/Diamond LED scribing wheels: |

Carbide scribing wheel |

We produce diamond glass cutters with high cost-performance ratio, which can be equipped with different types of diamond PCD scribing wheels such as high penetration PCD scribing wheels, standard PCD scribing wheels, hybrid PCD scribing wheels, carbide scribing wheels etc. |

Axles for the cutting wheel |

|

|

|

|

Diameter (mm) |

Length (mm) |

cone angle A (°) |

chamfer angle a (°) |

proper alignment (μm)

|

cylindricity (μm) |

roughness concentration

Ra (μm) |

||||||

2.0 |

2.5 |

3.6 |

4.0 |

4.5 |

6.0 |

8.0 |

||||||

0.8 |

★ |

★ |

★ |

★ |

★ |

★ |

★ |

120 |

45 |

5 |

2 |

0.2 |

1.0 |

★ |

★ |

★ |

★ |

★ |

|||||||

1.1 |

★ |

★ |

★ |

★ |

★ |

|||||||

1.2 |

★ |

★ |

★ |

★ |

★ |

|||||||

1.3 |

★ |

★ |

★ |

★ |

★ |

|||||||

1.4 |

★ |

★ |

★ |

★ |

★ |

|||||||

Diamond Axle, PCD Axle, Carbide Axle Features and advantages of diamond PCD axles: |

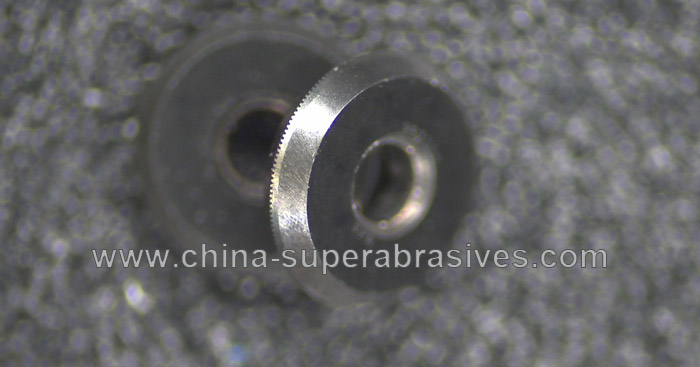

Diamond Glass Wheel holders |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We produce LED/glass cutting wheel holders, with reference to different applications as well as different types of glass cutting machine, we supply various holders with the best adaptability for the corresponding equipment to cut LCD panels and substrates, touch screen, common glass, glass tubes, tiles etc. One of the most important factors that influence productivity of glass cutting is the precision of wheel holders and the adaptability between wheels and holders, and precision and longevity of wheel holders are guaranteed. Features and advantages of wheel holders: |

Glass/LED screen cutting machine |

|

|

|

|

|

|

Single head glass cutting machine Features and advantages of single-head glass cutting machine: |

Multi-head glass cutting machine Features and advantages of multi-head glass cutting machine: |

Working table size |

380*180mm / 700*500mm |

Working table height |

680mm |

Glass cutting thickness |

0.1~2mm |

Minimum cutting size |

6*6mm |

Cutting distance tolerance |

~0.05mm |

Cross cut deviation of cutting line |

~0.02 / 400mm |

Number of cutters |

20 |

Gross weight |

150 kg |

Remark: The working table size can be customized, and machine must match with air compressor of 0.2~0.8Mpa, power of 0.75~1.5KW |

|

Glass cutting tools,engraver,grinding wheel |

|

|

|

|

|

|

|

|

|

|

| Glass diamond grinding wheel is used to grind the edges of ITO film glass and LCD glass. It is characterized by high efficiency and fineness of ground glass. |

| Glass twist drill is divided into two subcategories: 1). Sintered glass twist drill: with high cost-performance ratio, it is used to drill different thickness of glass. 2). Electroplated glass twist drill: it is used to drill small holes on thin glass. It is very sharp with relatively higher price. |

| Glass engraver is used to sculpt the glass, applications in glass, porcelain, tiles and granite. glass engraver is made of high grade PCD material which is welded onto the inserts and ground carefully. According to different processing ways, they are collapsed into the following subcategories: 1). Four square engraver: with long service life, it is applicable to various types of machinery for engraving line, edges, fonts and sculpture especially for carving granite and tiles. The maximum carving depth is 1mm. 2). Font engraver: it is mainly used to engrave 3-8CM fonts. It is characterized by high efficiency and long service life with the output of fonts of smooth edges and bottoms. The maximum carving depth is 4mm. 3). Milling bottom engraver: it is the solution to some milling problems for carbide tools for instance milling grooves and surfaces. It is characterized by high efficiency and long service life. The blade width is decided by the width of grooves and width of surfaces. The maximum carving depth is 2mm ideally. |

| Tel: 0086-731-89853480 Fax: 0086-731-89853490 Mobile: 0086-13875858570 |

E-mail: sales@china-superabrasives.com |