|

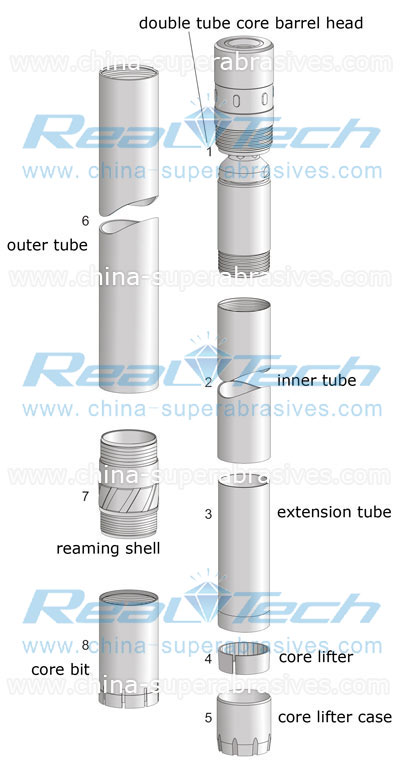

| Core Barrels of different types, T series core barrels(components incldue Double tube core barrel head,Inner tube,Extension |

| Tube,Core lifter, Core lifter case,Outer tube,Reaming shell,Core bit); WF series core barrels(components incldue Double tube |

| core barrel head,Inner tube,Ferrule,Core lifter, Core lifter case,Outer tube,Reaming shell,Core bit); series core barrels |

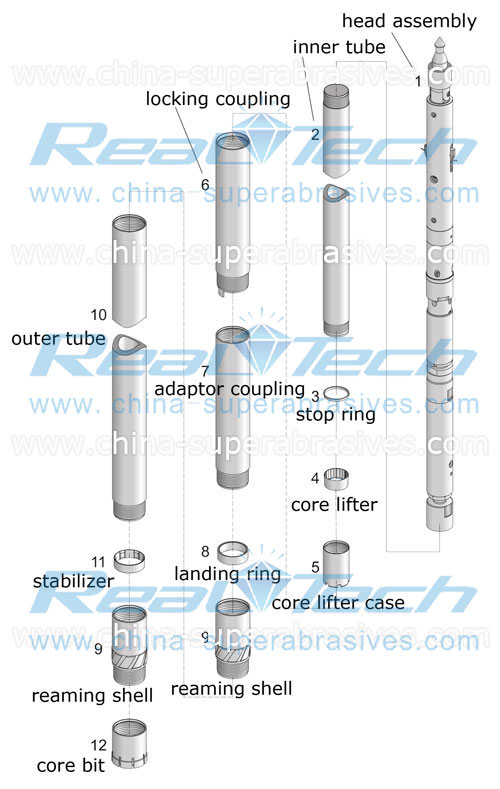

| (components incldue Inner tube head assembly,Inner Tube,Stop ring,Core lifter,Core lifter case,Locking Coupling,Adaptor |

| coupling,Landing Ring,Outer tube,Stabilizer,Reamming shell,Core bit); Single tube core barrels(components incldue Single tube |

| core barrel head,Single tube,Core lifter,Reaming shell,Core bit); Double tube core barrels(components incldue Double tube core |

| barrel head,Inner tube,Extension tube,Core lifter,Core lifter case,Outer tube,Reaming shell,Core bit); Wireline core barrels |

| (components incldue Head assembly,Inner tube,Stop ring,Core lifter,Core lifter case,Locking coupling,Adaptor coupling, |

| Landing ring,Reaming shell,Outer tube,Stabilizer,Core bit); Jet-type reverse circulation series(components incldue core barrel |

| head,Inner tube,Extension tube,Core lifter,Core lifter case,Outer tube,Reaming shell,Core bit) |

|

|

| Diamond core drilling |

Diamond core drilling (exploration diamond drilling) utilizes an annular diamond-impregnated drill bit attached to the end of hollow drill rods to cut a cylindrical core of solid rock. The diamonds used are fine to microfine industrial grade diamonds. They are set within a matrix of varying hardness, from brass to high-grade steel. Matrix hardness, diamond size and dosing can be varied according to the rock which must be cut. Holes within the bit allow water to be delivered to the cutting face. This provides three essential functions: lubrication, cooling, and removal of drill cuttings from the hole.

Diamond drilling is much slower than reverse circulation (RC) drilling due to the hardness of the ground being drilled. Drilling of 1200 to 1800 metres is common and at these depths, ground is mainly hard rock. Diamond rigs need to drill slowly to lengthen the life of drill bits and rods, which are very expensive.

Core samples are retrieved via the use of a core tube, a hollow tube placed inside the rod string and pumped with water until it locks into the core barrel. As the core is drilled, the core barrel slides over the core as it is cut. An "overshot" attached to the end of the winch cable is lowered inside the rod string and locks on to the backend(head assembly), located on the top end of the core barrel. The winch is retracted, pulling the core tube to the surface. The core does not drop out of the inside of the core tube when lifted because either a split ring core lifter or basket retainer allow the core to move into, but not back out of the tube.

Once the core tube is removed from the hole, the core sample is then removed from the core tube and catalogued. The Driller's assistant unscrews the backend off the core tube using tube wrenches, then each part of the tube is taken and the core is shaken out into core trays. The core is washed, measured and broken into smaller pieces using a hammer or sawn through to make it fit into the sample trays. Once catalogued, the core trays are retrieved by geologists who then analyse the core and determine if the drill site is a good location to expand future mining operations.

Diamond rigs can also be part of a multi-combination rig. Multi-combination rigs are a dual setup rig capable of operating in either a reverse circulation (RC) and diamond drilling role (though not at the same time). This is a common scenario where exploration drilling is being performed in a very isolated location. The rig is first set up to drill as an RC rig and once the desired metres are drilled, the rig is set up for diamond drilling. This way the deeper metres of the hole can be drilled without moving the rig and waiting for a diamond rig to set up on the pad. |

| Reverse circulation (RC) drilling |

RC drilling is similar to air core drilling, in that the drill cuttings are returned to surface inside the rods. The drilling mechanism is a pneumatic reciprocating piston known as a "hammer" driving a tungsten-steel drill bit. RC drilling utilises much larger rigs and machinery and depths of up to 500 metres are routinely achieved. RC drilling ideally produces dry rock chips, as large air compressors dry the rock out ahead of the advancing drill bit. RC drilling is slower and costlier but achieves better penetration than RAB or air core drilling; it is cheaper than diamond coring and is thus preferred for most mineral exploration work.

Reverse circulation is achieved by blowing air down the rods, the differential pressure creating air lift of the water and cuttings up the "inner tube", which is inside each rod. It reaches the "bell" at the top of the hole, then moves through a sample hose which is attached to the top of the "cyclone". The drill cuttings travel around the inside of the cyclone until they fall through an opening at the bottom and are collected in a sample bag.

The most commonly used RC drill bits are 5-8 inches (13–20 cm) in diameter and have round metal 'buttons' that protrude from the bit, which are reuired to drill through shale and abrasive rock. As the buttons wear down, drilling becomes slower and the rod string can potentially become bogged in the hole. This is a problem as trying to recover the rods may take hours and in some cases weeks. The rods and drill bits themselves are very expensive, often resulting in great cost to drilling companies when euipment is lost down the bore hole. Most companies will regularly re-grind the buttons on their drill bits in order to prevent this, and to speed up progress. Usually, when something is lost (breaks off) in the hole, it is not the drill string, but rather from the bit, hammer, or stabiliser to the bottom of the drill string (bit). This is usually caused by a blunt bit getting stuck in fresh rock, over-stressed metal, or a fresh drill bit getting stuck in a part of the hole that is too small, owing to having used a bit that has worn to smaller than the desired hole diameter.

Although RC drilling is air-powered, water is also used, to reduce dust, keep the drill bit cool, and assist in pushing cutting back upwards, but also when "collaring" a new hole. A mud called "Liui-Pol" is mixed with water and pumped into the rod string, down the hole. This helps to bring up the sample to the surface by making the sand stick together. Occasionally, "Super-Foam" (a.k.a. "uik-Foam") is also used, to bring all the very fine cuttings to the surface, and to clean the hole. When the drill reaches hard rock, a "collar" is put down the hole around the rods, which is normally PVC piping. Occasionally the collar may be made from metal casing. Collaring a hole is needed to stop the walls from caving in and bogging the rod string at the top of the hole. Collars may be up to 60 metres deep, depending on the ground, although if drilling through hard rock a collar may not be necessary.

Reverse circulation rig setups usually consist of a support vehicle, an auxiliary vehicle, as well as the rig itself. The support vehicle, normally a truck, holds diesel and water tanks for resupplying the rig. It also holds other supplies needed for maintenance on the rig. The auxiliary is a vehicle, carrying an auxiliary engine and a booster engine. These engines are connected to the rig by high pressure air hoses. Although RC rigs have their own booster and compressor to generate air pressure, extra power is needed which usually isn't supplied by the rig due to lack of space for these large engines. Instead, the engines are mounted on the auxiliary vehicle. Compressors on an RC rig have an output of around 1000 cfm at 500 psi (500 L·s−1 at 3.4 MPa). Alternatively, stand-alone air compressors which have an output of 900-1150cfm at 300-350 psi each are used in sets of 2, 3, or 4, which are all routed to the rig through a multi-valve manifold. |